“Necessity is the mother of invention.” ~Proverb.

Some months back I was enjoying the sport that fishing for spring stocky trout gave me with an ultralight Lew’s reel and 2lb monofilament.

Unfortunately, as is so often the case when fishing spinners with monofilament, the line worked up a bit of memory and after one fateful cast I had a loop in my line that wrapped around and under the spool.

On any other day, this would have been no big deal. I undid my drag and pulled the spool off to free the loop.

But on this particular day, as fate would have it, a small, clear plastic washer – the spool tensioner washer – slipped off the end of the spool axle.

I wonder where we get expressions like “needle in a haystack” when we can use much more fitting and accurate expressions like “spool tensioner washer on a muddy creekbed.”

I tell you with no lick of sarcasm I would fain search for a needle in a haystack sooner.

I believe I have already told you in so many words that washer was gone as gone gets. I did waste a few moments of my life that I will never recover in the search but not only the futility of it but the comedy of it was soon apparent to me.

So I stopped wasting my time, freed the line of its loops, rewound the line on the spool, replaced the spoon on the axle and reset the drag.

I went back to fishing, and let me tell you if you’ve never lost your spool tension washer, the reel works just fine without it.

Except, at the bottom of the spool’s travel, it will bang quite coarsely into the bottom of the other metal washer that serves as a drag alarm.

That is, the reel will function just fine, but not smoothly – and smooth is an imperative if you are fishing with 2lb line.

So I knew right then if I didn’t come up with some sort of solution my day of fishing was effectively over.

As fate would also have it I had a small plastic HDPE cup that until recently had served as a vessel for an iced coffee I was drinking creekside.

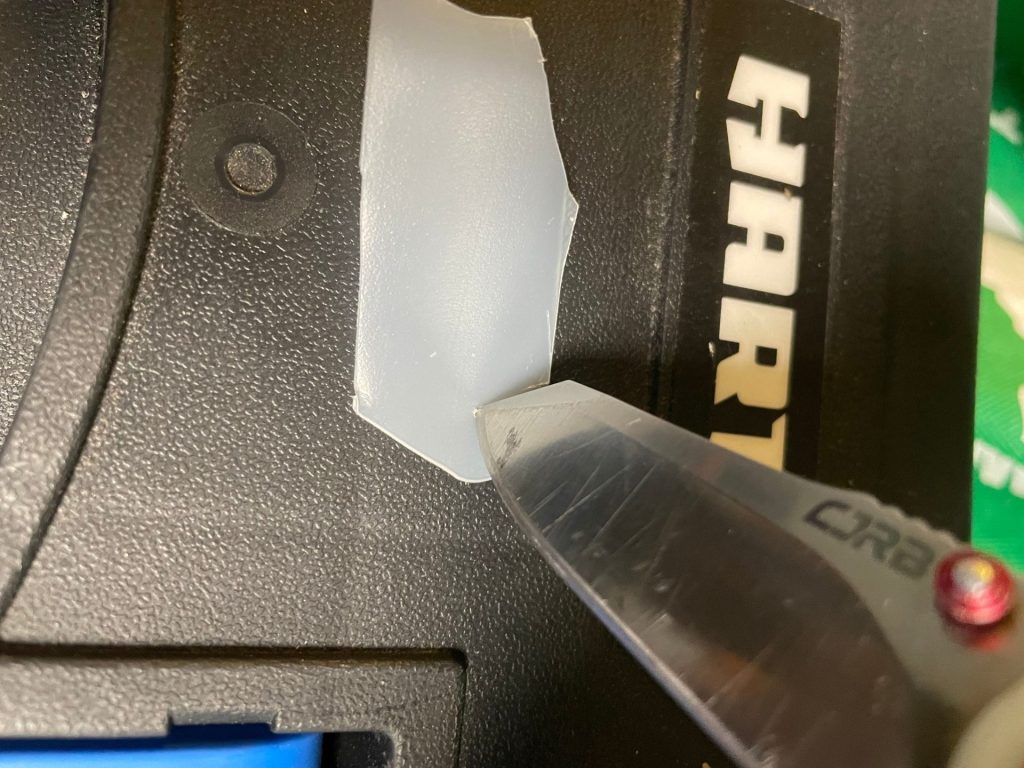

I whipped out my CJRB Maileah and trimmed off a bit of plastic from the cup, roughly in the proper dimensions of my original (and now long-gone) spool tensioner washer, drilled a hole through it with the point of the knife, slipped that over the spool axle, dropped the spool back on, set the drag, and was back to fishing.

Here’s my original creekside fix. A bit coarse, but she worked.

I daresay that Lew’s ran more smoothly than she did on our inaugural creekside journey.

And so this experience has inspired me to save you from the same trouble.

Those spool tension washers, usually slick with grease, typically stay right in place on the reel axle when you take the spool off.

But when they don’t they go flying and more often than not, never to be recovered.

If you ever lose yours, don’t hang up the reel, and whatever you do, don’t pay several dollars to replace a part so insignificant in economic value that its cost can’t be calculated in pennies.

You can buy replacements; I say you make your own.

You’ll need a milk jug. Rinse it out until it’s perfectly clean.

Cut off a small piece of this that you can work with, again, ensuring it is perfectly clean. Dry it off, then punch a small hole through it. You can use a nail, an awl, the point of your knife; I’m using a hook tool.

Then, using either a very sharp knife or a pair of scissors or shears, cut it to shape. The size you will need for each reel is different, but here’s the rule of thumb.

It should be as round as possible, and only so wide in diameter that it covers the inner diameter of the metal washer beneath it with teeth that serves as a drag alarm.

Below they are, overlaid, so you can see what they look like when assembled. If you make the washer too large, the reel will still work, but the drag alarm won’t. So you want your new one to be sized properly so the parts nest as they are intended.

I needed to trim mine just a bit more. You can see the finished product at the top of this post; it’s the first image.

Rest assured, when I assembled the reel, it sang along just fine. So smoothly, in fact, that I took her on the dock and pulled in a pickerel and a nesting bass in just as many casts.

Since this is a part that’s all too easy to lose, I hope my jury-rigged fix serves you well. Hopefully you landed on my post before you shelled out good money to make a fix you could have made just as well yourself.

Stay sharp.

~The Eclectic Outfitter